|

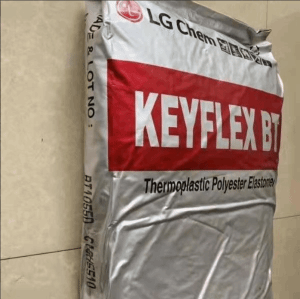

| 品牌 | LG工程塑料 |

| 货号 | 300 |

| 用途 | 配件 |

| 牌号 | BT-1172D |

| 型号 | BT-1172D |

| 品名 | TPEE |

| 外形尺寸 | 25/kg |

| 厂家 | LG工程塑料 |

| 是否进口 | 否 |

韩国LG电线电缆TPEE KEYFLEX BT 1172D

|

Density / Specific Gravity |

1.25 |

g/cm3 |

ASTM D792 |

|

Melt Mass-Flow Rate (MFR) (230°C/2.16 kg) |

15 |

g/10 min |

ASTM D1238 |

|

Molding Shrinkage - Flow (23°C, 3.20 mm, Injection Molded) |

1.5 to 1.9 |

% |

ASTM D955 |

|

Water Absorption (24 hr, 23°C) |

0.30 |

% |

ASTM D570 |

| Hardness |

Nominal Value |

Unit |

Test Method |

|

Durometer Hardness (Shore D, 23°C, Injection Molded) |

66 |

ASTM D2240 |

| Mechanical |

Nominal Value |

Unit |

Test Method |

|

Tensile Strength 3 |

ASTM D638 | ||

|

Yield, 23°C, 2.00 mm, Injection Molded |

24.5 |

MPa |

|

|

Break, 23°C, 2.00 mm, Injection Molded |

49.0 |

MPa |

|

|

Tensile Elongation 3 (Break, 23°C, 2.00 mm, Injection Molded) |

600 |

% |

ASTM D638 |

|

Flexural Modulus 4 (23°C, 6.40 mm, Injection Molded) |

441 |

MPa |

ASTM D790 |

| Elastomers |

Nominal Value |

Unit |

Test Method |

|

Tear Strength 3 (23°C) |

165 |

kN/m |

ASTM D624 |

| Impact |

Nominal Value |

Unit |

Test Method |

|

Notched Izod Impact |

ASTM D256 | ||

|

-40°C, 6.40 mm, Injection Molded |

44 |

J/m |

|

|

23°C, 6.40 mm, Injection Molded |

150 |

J/m |

| Thermal |

Nominal Value |

Unit |

Test Method |

|

Deflection Temperature Under Load (0.45 MPa, Unannealed, 6.40 mm, Injection Molded) |

130 |

°C |

ASTM D648 |

|

Peak Melting Temperature |

217 |

°C |

ASTM D3418 |

| Electrical |

Nominal Value |

Unit |

Test Method |

|

Volume Resistivity |

> 1.0E+13 |

ohms·cm |

ASTM D257 |

|

Dielectric Strength (1.00 mm) |

26 |

kV/mm |

ASTM D149 |

|

Comparative Tracking Index (Solution A) |

600 |

V |

IEC 60112 |

TPEE具有的耐油性,在室温下能耐大多数极性液体化学介质(如酸、碱、胺二醇类化合物),但对卤代烃(氟里昂除外)及酚类的作用却无能为力,其耐化学品的能力随其硬度的提高而提高。TPEE对大多数有机溶剂、燃料及气体的抗溶胀性能和抗渗透性能是好的,对燃油渗透性仅为氯丁胶、氯磺化聚乙烯、丁腈胶等耐油橡胶的1/3~1/300但TPEE耐热水性较差,添加聚碳酰亚胺稳定剂可以其抗水解性能。