|

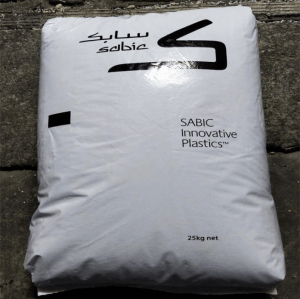

| 品牌 | 沙特基础 |

| 货号 | 100 |

| 用途 | 配件 |

| 牌号 | GTX942 |

| 型号 | GTX942 |

| 品名 | PPO |

| 外形尺寸 | 25/kg |

| 厂家 | 沙特基础 |

| 是否进口 | 是 |

美国沙比克高流动耐化学PPE/PA NORYL GTX942

NORYL GTX GTX942 Resin is a blend of Polyphenylene Ether(PPE) + Polyamide(PA) resin that is designed to have high melt flow for large part/thinwall injection molding. The material is designed to have the excellent chemical resistance and paintability as other NORYL GTX Resins.

|

Density / Specific Gravity |

1.09 |

g/cm3 |

ASTM D792, ISO 1183 |

|

Melt Mass-Flow Rate (MFR) (280°C/5.0 kg) |

19 |

g/10 min |

ASTM D1238 |

|

Melt Volume-Flow Rate (MVR) (280°C/5.0 kg) |

17 |

cm3/10min |

ISO 1133 |

|

Molding Shrinkage - Flow (3.20 mm) |

1.1 to 1.3 |

% |

Internal Method |

|

Water Absorption |

ISO 62 | ||

|

Saturation, 23°C |

1.0 |

% |

|

|

Equilibrium, 23°C, 50% RH |

0.52 |

% |

|

Charpy Notched Impact Strength 6 (23°C) |

23 |

kJ/m2 |

ISO 179/1eA |

|

Notched Izod Impact |

|||

|

-30°C |

120 |

J/m |

ASTM D256 |

|

23°C |

270 |

J/m |

ASTM D256 |

|

-30°C 7 |

15 |

kJ/m2 |

ISO 180/1A |

|

23°C 7 |

22 |

kJ/m2 |

ISO 180/1A |

|

Instrumented Dart Impact (23°C, Total Energy) |

46.0 |

J |

ASTM D3763 |

| Thermal |

Nominal Value |

Unit |

Test Method |

|

Deflection Temperature Under Load |

|||

|

0.45 MPa, Unannealed, 3.20 mm |

160 |

°C |

ASTM D648 |

|

0.45 MPa, Unannealed, 4.00 mm, 64.0 mm Span 7 |

154 |

°C |

ISO 75-2/Bf |

|

Vicat Softening Temperature |

|||

|

-- |

171 |

°C |

ASTM D1525 8 |

|

-- |

169 |

°C |

ISO 306/B50, ISO 306/B120 |

PPO是 五大通用工程塑料之一。它具有刚性大、耐热性高、难燃、强度较高电性能优良等优点。另外,PPO还具有 耐污染等优点。PPO的介电常数和介电损耗在工程塑料中是 小的品种之一,几乎不受温度、湿度的影响,可用于低、中、高频电场领域。PPO的负荷变形温度可达 190℃以上,脆化温度为-170℃。