|

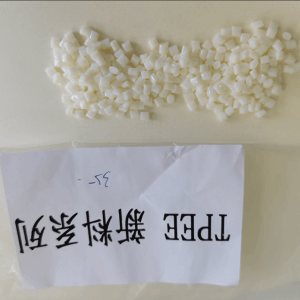

| 品牌 | SK |

| 货号 | 100 |

| 用途 | 配件 |

| 牌号 | LX770A |

| 型号 | LX770A |

| 品名 | TPEE |

| 外形尺寸 | 25/kg |

| 厂家 | 韩国SK |

| 是否进口 | 否 |

SKYPEL的介绍

|

Skypel结合工程塑料及橡胶特性于一体,能为传统及工程塑料创出新的应用领域。

|Skypel属于高性能级别的工程橡胶,有 的韧性、回弹性、抗低温挠曲疲劳性,耐油、脂及多种化学溶剂及工业化学品。

||

|

物性

| | | | | | | | | | | | | || | | | | | | | | | | || | | | | | | | | | | || | | | | | | | | | | || | | | | | | | | | | || | | | | | | | | | | || | | | | | | | | | || | | | | | | | | | || | | | | | | | | | || | | | | | | | | | | || | | | | | | | | | | || | | | | | | | | | | || | | | | | | | | | | || | | | | | | | | | | || | | | | | | | | | | || | | | | | | | | | | || | | | | | | | | | ||||

|

测试项目 | |

|

测试方法 | |

|

单位 | |

|

G130D | |

|

G140D | |

|

G155D | |

|

G163D | |

|

G168D | |

|

G172D | |

|

G182D | |

|

|

硬度 | |

|

ASTM D2240 | |

|

Shore D | |

|

30 | |

|

40 | |

|

55 | |

|

63 | |

|

68 | |

|

72 | |

|

77 | |

|

|

比重 | |

|

ASTM D792 | |

|

* | |

|

1.07 | |

|

1.16 | |

|

1.18 | |

|

1.21 | |

|

1.24 | |

|

1.25 | |

|

1.27 | |

|

|

含水率 | |

|

ASTM D570 | |

|

% | |

|

0.8 | |

|

0.6 | |

|

0.50 | |

|

0.3 | |

|

0.3 | |

|

0.3 | |

|

0.2 | |

|

|

缩水率 | |

|

ASTM D955 | |

|

% | |

|

0.4 | |

|

0.8 | |

|

1.20 | |

|

1.5 | |

|

1.6 | |

|

1.7 | |

|

2.2 | |

|

|

5%拉伸强度 | |

|

ASTM D638 | |

|

kgf/cm2 | |

|

6 | |

|

24 | |

|

65 | |

|

110 | |

|

150 | |

|

230 | |

|

300 | |

|

|

10%拉伸强度 | |

|

kgf/cm2 | |

|

18 | |

|

44 | |

|

115 | |

|

175 | |

|

240 | |

|

300 | |

|

400 | |

|

|

|

拉伸强度 | |

|

kgf/cm2 | |

|

220 | |

|

270 | |

|

400 | |

|

440 | |

|

460 | |

|

470 | |

|

500 | |

|

|

|

断裂伸长率 | |

|

% | |

|

900 | |

|

680 | |

|

600 | |

|

500 | |

|

450 | |

|

420 | |

|

350 | |

|

|

|

弯曲模量 | |

|

ASTM D790 | |

|

kgf/cm2 | |

|

280 | |

|

680 | |

|

2100 | |

|

3200 | |

|

4700 | |

|

5500 | |

|

9000 | |

|

|

撕裂强度 | |

|

ASTM D1004 | |

|

kN/m | |

|

95 | |

|

115 | |

|

165 | |

|

180 | |

|

193 | |

|

205 | |

|

260 | |

|

|

缺口冲击强度 | |

|

ASTM D256 | |

|

kgf/cm | |

|

N.B. | |

|

N.B. | |

|

N.B. | |

|

N.B. | |

|

23 | |

|

12 | |

|

4 | |

|

|

垂直回弹率 | |

|

ASTM D2632 | |

|

% | |

|

72 | |

|

57 | |

|

55 | |

|

53 | |

|

47 | |

|

* | |

|

* | |

|

|

软化点 | |

|

ASTM D3418 | |

|

℃ | |

|

174 | |

|

155 | |

|

202 | |

|

212 | |

|

215 | |

|

218 | |

|

222 | |

|

|

热变形温度 | |

|

ASTM D648 | |

|

℃ | |

|

* | |

|

70 | |

|

105 | |

|

130 | |

|

140 | |

|

150 | |

|

156 | |

|

|

流动指数 | |

|

ASTM D1238 | |

|

g/10min | |

|

18 | |

|

7 | |

|

20 | |

|

10 | |

|

13 | |

|

13 | |

|

8 | |

|

|

测试温度 | |

|

℃ | |

|

220 | |

|

190 | |

|

220 | |

|

230 | |

|

230 | |

|

230 | |

|

230 | |